WELCOME TO VISIT OUR OFFICIAL WEBSITE,TO LEARN MORE SLURRY PUMP!

WhatsApp / WeChat : +86 13383213680

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

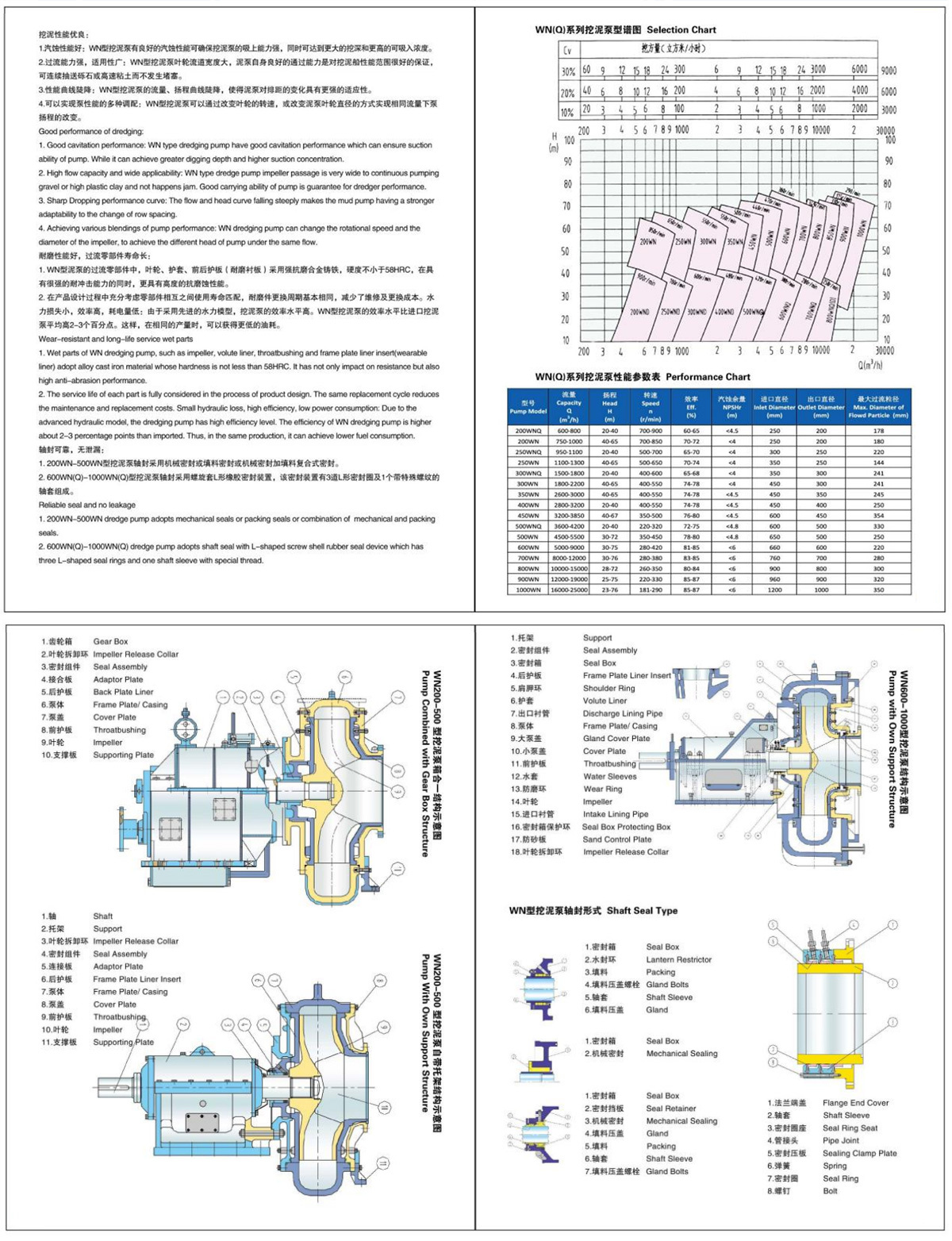

WN Series Dredging Pump

Categories:

Diameter: 200~1000 mm

Flow rate: 600~25000 m3/h

Head: 20~75 m

Type Notation:

450WN(Q)

450:Discharge diameter (mm)

WN:Dredge pump

Q:Submersible dredge pump

WhatsApp / WeChat:

+86 13383213680

Email:

Product introduction

Product introduction:

WN Series Pump: The Impeller, guard plate, pump body, bracket, and shaft are made of metal material.

WN series dredging pump is a kind of highly effective wear-resistant marine dredging pump, which is based on the absorption of aboard technology.

WN dredging pump For sale meets the comprehensive dredging requirement at home and abroad.

Structural Features:

Over structure performance well in marine use:

Simple and reliable structure: This type of dredge pump with a single pump casing or double pump casing, single casing stage, single suction, cantilever, and horizontal structure.

According to the connection type with the gearbox, there are two kinds of typical structures, one is with independent support, and the other is combined with gearbox. The lubrication of the pump with support is grease lubrication or thin oil lubrication.

The double casing design can make the pump body safe even when the liner is worn out. Easy to disassemble and maintain: WN-type dredging pump can be disassembled from the front. This makes the disassembly and maintenance easier.

Good performance of dredging:

1. Good cavitation performance: WN-type dredging pumps have good cavitation performance which can ensure the suction ability of the pump.While it can achieve greater digging depth and higher suction concentration.

2. High flow capacity and wide applicability: WN-type dredge pump impeller passage is very wide to continuously pump gravel or high plastic clay and not jam. The good carrying ability of the pump is guaranteed for dredger performance.

3. Sharp Dropping performance curve: The flow and head curve failing steeply makes the mud pump have a stronger adaptability to the change of row spacing.

4. Achieving various blending of pump performance: The WN dredging pump can change the rotational speed and the diameter of the impeller, to achieve the different heads of the pump under the same flow.

5. Wear-resistant and long-life service wet parts:

1. Wet parts of the WN dredging pump, such as the impeller, volute liner, throat bushing, and frame plate liner insert(wearable liner) adopt alloy cast iron material whose hardness is not less than 58 HRC. It not only impacts resistance but also high anti-abrasion performance.

2. The service life of each part is fully considered in the process design. The same replacement cycle reduces the maintenance and replacement costs. Small hydraulic loss, high efficiency, low power consumption: Due to the advanced hydraulic model, the dredging pump has a high-efficiency level. The efficiency of the WN-type dredging pump is higher about 2-3 percentage points than that imported. Thus, in the same production, it can achieve lower fuel consumption.

Reliable seal and no leakage

1.200WN-500WN dredge pump adopts mechanical seals or combination and packing seals.

2.600WN-1000WN dredge pump adopts shaft seal with L-shaped screw shell rubber seal device which has three L-shaped seal rings and one shaft sleeve with special thread.

WN Series Pump: The Impeller, guard plate, pump body, bracket, and shaft are made of metal material.

Production capacity

The total design and production capacity of our factory is 10,000 units (sets) per year, and we can produce 2,000 tons of various high-chromium alloy castings annually. The production area currently includes the following production zones. Namely:casting workshop, heat treatment workshop, machining workshop, metal forming and welding workshop,assembly and painting workshop, spare parts warehouse and finished parts warehouse; Two centers:quality inspection and analysis center and the overall hydraulic test center.

Our products are mainly made of high-chromium wear-resistant white cast iron such as A05, A07, A49, A33, etc. The product development and process formulation all adopt CFD and CAPP new technologies. All castings use resin sand molding and newly introduced lost foam casting technology, which can pour 8-10 tons of castings at one time. The heat treatment workshop has two 20 cubic electric resistance heat treatment furnaces, and the machining shop has two large vertical lathes of 4.2M and 4.5M and more than 20 other types of machine tools. In addition,there are various types of hoisting equipment,metal cutting and welding equipment,impeller level tuning equipment,molding equipment,sandblasting polishing equipment.

Our main products includes a full range of slurry pumps, desulfurization pumps, gravel pumps, dredging pumps, foam pumps, chemical process pumps, PU rubber slurry pumps, and other dozens of varieties, hundreds of models.Widely used in mining (mineral processing), metallurgy, coal, power plant, flue gas desulfurization, silt dredging, sewage treatment industries, chemicals, municipal and environmental protection and so on.

keywords:

ONLINE CONSULTING

English

English 中文版

中文版 Русский

Русский Français

Français